Queenbee Pro Machine

At a glance

- Advanced complete redesign of Workbee to incorporate linear rails, heavier components

- Available in 1000×1000 mm only

- We do not recommend or sell the 1500×1000 or 1500x1500mm kits because we believe them to be inferior machines

- NEMA23 Enhanced Torque Motors (1.9Nm, 269 oz/in.)

- Screw Drive on X,Y, Z Axes with Tingle Tension System on X and Y axes eliminates lead screw whip at high speeds.

- Double router mount available

- Electronics sold separately for kits

- Mechanical parts Kits (motors included) Starting at $2395.00

- Much stiffer rails, thicker 10mm plates, raised Z axis 2″, smooth accurate linear rail/bearing motions system

- We can also supply these machines fully assembled and tested!

- Kits do not include spoil board, some items in photos may be options

- NEW! Upgrade kits available for your standard Workbee 1010

Click on the orange bar to expand the accordion for more info!

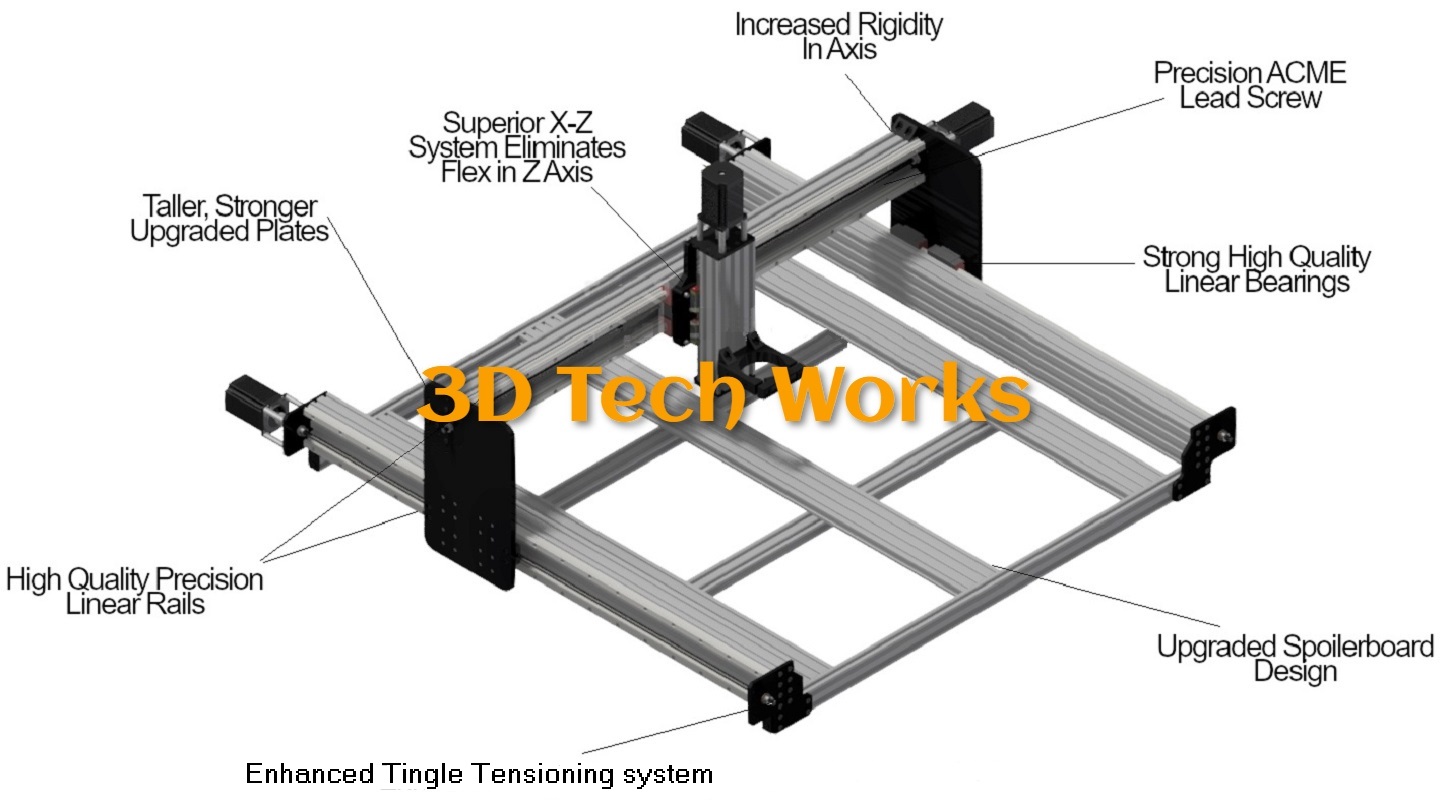

The Workbee is a robust CNC router platform. The QueenBee Pro is a complete redesign of the WorkBee with the latest performance enhancements designed to improve accuracy, reliability, and capacity. It is made entirely of extruded aluminum sections with good strength and rigidity, enhanced over the WorkBee design with added extrusions for rigidity, thicker plates for increased strength, and the replacement of all the polycarbonate wheels with high precision linear rails and bearing carriages. A redesigned base with front and back full width legs and enhanced support provides stability, and C-Beam extrusions form the axis tracks.

The kits include all mechanical parts needed for the machine, including enhanced torque 1.9 Nm NEMA 23 motors. The machine also incorporates the lead screw tensioning system, a method for keeping the lead screws in tension, virtually eliminating lead screw whip at high speeds.

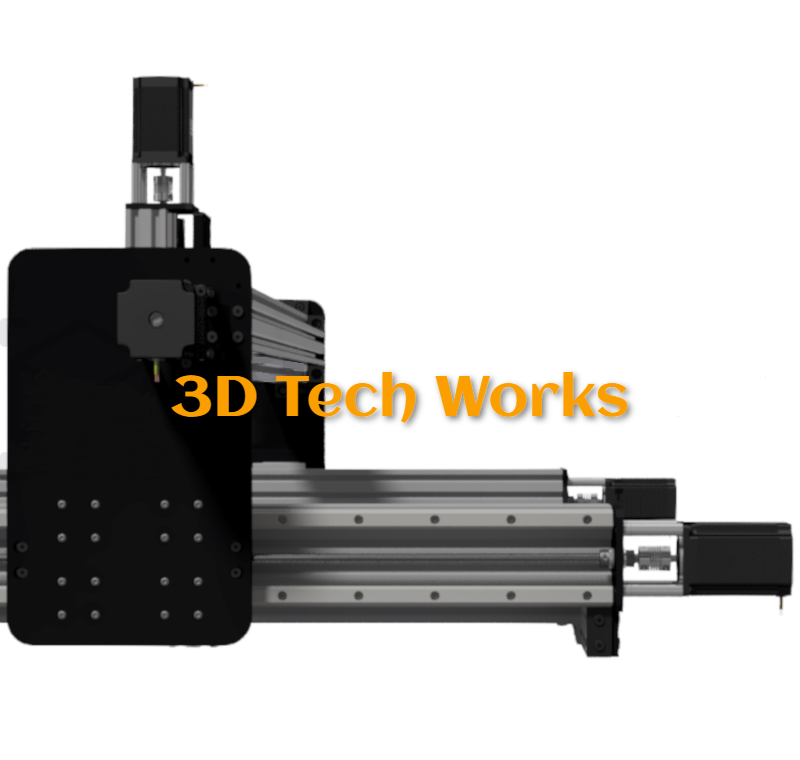

The X-Z axis carriage has 2 linear rails with 4 bearing carriages each to support the X and Z axes. These linear rails replace the outdated wheel system of all previous OB designs. Not only are they more accurate, with less play, but they are smoother and nearly frictionless. The hardened steel rails are bolted to the extrusions using dozens of small screws to distribute the load. These rails add a significant amount of stiffness to the extrusions. Additionally an extra extrusion is bolted to the back of the X axis c-beam rail to increase stiffness even more.

The Y axis carriages are based on thicker 10mm plates, with 4 linear bearing carriages riding on 2 steel rails per side. This dramatically increases strength, along with additional extrusion inserts in the Y axis c-beam for even more stiffness. The Y carriage plates have the X beam mounting holes moved back to give the machine more useable machinable area.

The Z-Axis C-Beam extrusion is 250mm in length, with a travel of nearly 140mm. The Z axis is supported by its own 4 carriage linear rail system. The Z-Axis actuator is lead screw driven by a top mounted stepper motor. A 71mm heavy router mount is an option to use a Bosch Colt or a Dewalt Router. A 65mm router mount is also available to mount Makita routers and some DC spindles. An 80mm mount is available for 1.5 and 2.5 Kw VFD spindles as well. Double router mounts can also be accommodated for extra strength.

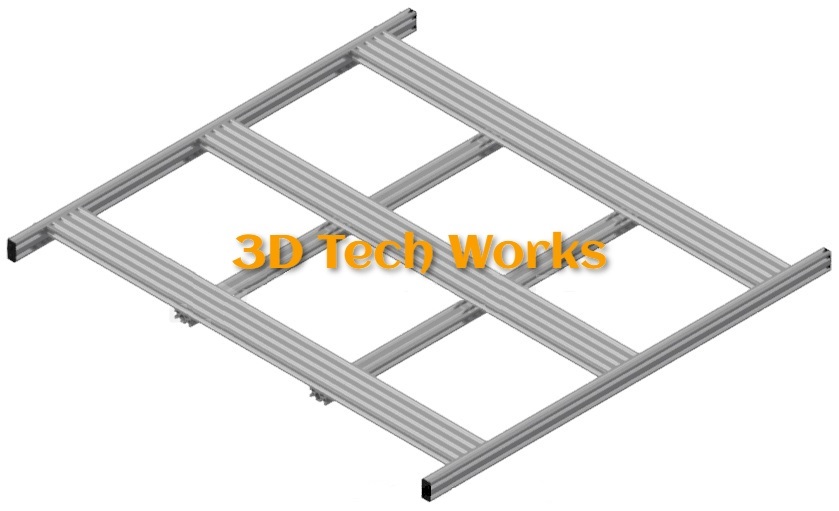

An MDF spoil board is mounted in the bottom of the frame. (Not included). The spoil board is bolted to the frame around the perimeter to enhance strength and rigidity. The base support frame uses an improved design with cross beams bolted at intersection points for improved stiffness and flatness.

- Bed area Sizes available: 1000x1000mm

- Active area 1000x1000mm – Approx 840x755x140mm

- Screw drive with Tensioning System on X,Y axes

- Standard with 325 Oz-in NEMA 23 motors

- All mechanical parts included

- Basic GRBL Electronics package included, can be upgraded to MACH3 compatible system or Xpro V5 controller

These Chinese kits are excellent quality. They include wiring kits, cable chain, and some other minor parts like bed mounting hardware and router mount. They can be equipped with Xpro V5 controllers with Wi-Fi, SD Card, and easy to wire up plug and play wiring system,

Options available

- Dewalt DWP611 router, variable speed, soft start, 1/4″ chuck OR

- Makita router, RT0701 variable speed, 1/4″ chuck OR

- VFD water cooled 1.5Kw spindle, with VFD drive, spindle motor, cable, and pump with tubing

- Double Router mount – specify router type when ordering – double router mount for extra strength

- Electronic Homing / Limit Switch Package

- Z probe – Z only, or XYZ

- Full Electronics package available for kits, including Hi Torque GRBL, Xpro V5, and UC300 package

- Router on/off remote control module (not compatible with VFD spindle)

- Dust Boot

- Power Line Conditioner – protects electronics from noise and damage (Highly recommended, Required for warranty coverage on Turnkey machines)

- Prices subject to change without notice.

- Prices subject to fluctuation in US/CDN dollar conversion.

- Prices do not include taxes or shipping and handling.

- All pricing FOB Calgary, Alberta

- Pricing for these items is preliminary and may change*

These are Chinese made kits and are imported directly from China. Delivery times are typically 2 weeks but Covid protocols may cause delays in shipping.

- 1000x1000mm complete kit screw drive – with 1.5Kw VFD Spindle, GRBL Enhanced controller, wiring kit, homing switches, cable chain kit $2995.00 CDN

- 1010 Upgrade kit, to upgrade existing V2.2 WB1010 machine to full QB Pro, includes rails and linear bearings, plate set, extra extrusions, all hardware. Note that this is an upgrade kit only, you need to already have a standard functional Workbee machine. Higher torque motors can be supplied as an extra cost option $1295.00 CDN